Managing the cost of a gantry crane is a crucial aspect for businesses involved in heavy lifting operations. Whether for manufacturing, shipping, or construction, controlling the expenses associated with acquiring and operating a gantry crane can significantly impact the overall profitability of a project. Below are the key factors you should consider to effectively control gantry crane costs.

Selecting the Right Crane for Your Needs

Choosing a gantry crane that matches your specific operational requirements is the first step in managing costs. Avoid overspending on features or capacities you do not need, but also ensure the crane meets all essential needs to prevent future upgrades or replacements. Consider the following:

Load Capacity: Determine the maximum weight the crane needs to lift.

Span and Height: Accurately measure the working area to ensure proper dimensions.

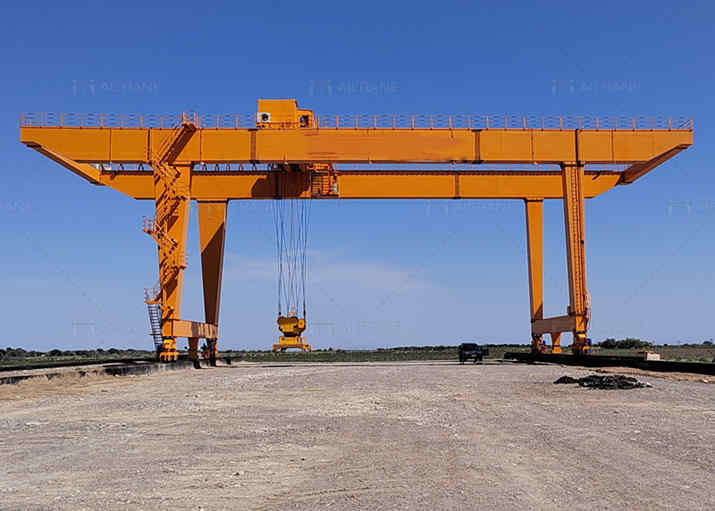

Indoor or Outdoor Use: Cranes designed for outdoor use often require additional weatherproofing, impacting cost.

Quality of Materials and Construction

The material quality and design of the gantry crane play a significant role in its cost. High-quality steel and durable components may cost more initially but reduce long-term expenses by minimizing repairs and replacements. Ensure the gantry crane manufacturer provides detailed specifications about:

Material Grade: Look for high-tensile, corrosion-resistant steel for longevity.

Weld Quality: Poorly welded joints may fail under stress, leading to costly repairs.

Comparing Suppliers

To control costs, compare multiple suppliers and manufacturers before making a decision. When comparing options:

Request Multiple Quotes: Get itemized quotations from at least three suppliers.

Check Reputation: A reputable manufacturer may charge more upfront but ensure better reliability and after-sales support.

Negotiate Prices: Many suppliers offer discounts for bulk orders or recurring customers.

Customization and Additional Features

Customized gantry cranes with advanced features often cost more. To control expenses:

Evaluate Necessity: Only opt for customization if it’s essential for your operations.

Avoid Over-Specification: Features like remote controls or automation may be nice to have but could increase costs unnecessarily.

Installation and Setup Costs

The installation process for gantry cranes can be expensive, especially for larger or more complex models. Reduce these costs by:

Choosing Prefabricated Designs: Prefabricated models are easier and faster to install.

Hiring Local Installation Teams: Local professionals may charge less than international crews.

Ensuring Site Preparation: Proper preparation of the installation site prevents delays and additional charges.

Maintenance and Repair Costs

While initial purchase costs are significant, operational and maintenance expenses also add up. Reduce these costs by:

Regular Maintenance: Scheduled maintenance keeps the crane in optimal condition, preventing expensive repairs.

Using Genuine Parts: Invest in original spare parts to avoid compatibility issues or premature failures.

Training Operators: Well-trained operators minimize misuse and wear and tear, reducing repair frequency.

Energy Efficiency

Operating costs can escalate if the crane consumes excessive energy. Choose energy-efficient models to save on electricity or fuel:

Opt for Advanced Motors: Modern motors are more energy-efficient and reduce operational costs.

Consider Renewable Power Options: Solar-powered or hybrid electric gantry cranes can lower long-term energy expenses.

Warranty and After-Sales Service

A good warranty and reliable after-sales service can significantly impact costs over the crane’s lifespan. When selecting a manufacturer, inquire about:

Warranty Coverage: Ensure it includes key components like motors, controls, and structural elements.

Service Plans: Some manufacturers like Aicrane offer affordable service packages that cover routine maintenance and emergency repairs.

Resale Value

The resale value of a gantry crane can offset the initial purchase cost when upgrading or changing equipment. Choose cranes with high resale potential by:

Selecting Renowned Brands: Well-known brands tend to retain their value better.

Maintaining Detailed Records: Keep maintenance and usage logs to demonstrate the crane’s condition.

Lifespan and Durability

Investing in a durable, long-lasting gantry crane is a cost-effective strategy. Although the initial cost might be higher, the extended lifespan reduces the need for frequent replacements. Look for features such as:

Weatherproofing for Outdoor Use: Protects the crane from corrosion and environmental damage.

Advanced Coatings: Anti-corrosion and wear-resistant coatings enhance durability.

Controlling gantry crane costs involves a careful balance between upfront investment and long-term savings. By focusing on selecting the right model, ensuring quality construction, comparing suppliers, and managing operational expenses, businesses can achieve cost efficiency without compromising performance. Always prioritize durability, energy efficiency, and maintenance support to maximize the value of your investment.