A belt type concrete batching plant is used in projects where huge amount of concrete is needed. It offers a number of advantages such as precise mixing and efficient production of concrete at a quick pace. Since belt conveyors are used in this type of plant, it helps in increasingly efficiency and capacity of the plant.

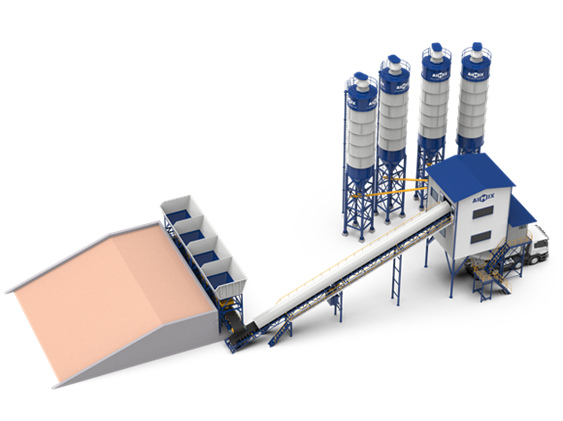

These plants are sold in various capacities which is usually measured in cubic meters of concrete produced in an hour. Since belt conveyors are used in this type of plant, a huge amount of land is required for installation of these plants. Therefore, before you begin to plan for installation of a batching plant, it is important for you to earmark the land required for setting up such a plant. As far as the main components of a concrete batching plant are concerned, it has a number of components such as the mixing system, weighing system for the material, conveying system for the material, storage system for the materials as well as control system for the plant: https://aimix.my/belt-type-concrete-batching-plant/

The material weighing system consists of several different components to accurately weigh water, fly ash, cement, aggregate and other things needed for making concrete. These are controlled by a computerized control system to ensure complete accuracy. Similarly, all the other systems such as conveyor system, mixing system and storage system are operated by a centralized computer system to ensure complete accuracy and high level of automation.

As far as buying a concrete mixing plant is concerned, there are several manufacturers of these plants spread all across the world. You should not buy such an expensive plant without proper research. Since every single concrete plant is a unique project, you need to find a supplier who is willing to customize their approach based on your unique requirements. You might want to increase the number of weighing hoppers or you might want to increase the length of belt conveyors depending on your own unique requirements. Therefore, the manufacturer should be flexible enough to conform to your unique requirements instead of trying to sell the standard plant available with them.

They should also offer pre-sale as well as after sale service. Before the sale is finalized, you should visit their manufacturing facility to ensure they have proper quality control processes in place. Lack of quality control usually means that they do not supervise the production of components in their factory. It could be a big problem in ensuring quality of the components in the delivered plant. They should also have engineers willing to travel to your location to ensure error free installation of the concrete batching plant.

The after-sale service is also important. There are lot of moving components in a concrete batching plant and these components will fail after some time. You will need regular availability of these components to ensure your ready mix plant keeps working without any issues. Therefore, availability of affordable spare parts and timely availability of service and maintenance engineers is necessary to ensure smooth operation. Make sure they have a local service and maintenance office where optimum number of engineers should be always available to ensure dealing with any kind of problems in a smooth manner.

Overall, a concrete batching plant offers a number of advantages and this is the reason, it is widely used in projects where huge amount of concrete is needed. Keep the above mentioned tips in mind to get the best value for your money when buying a concrete batching plant. To learn more, click here https://www.aimix.my/